Sixteen years after the launch of Google Talk, Google messaging is still a mess.

Google Talk, Google’s first-ever instant messaging platform, launched on August 24, 2005. This company has been in the messaging business for 16 years, meaning Google has been making messaging clients for longer than some of its rivals have existed. But thanks to a decade and a half of nearly constant strategy changes, competing product launches, and internal sabotage, you can’t say Google has a dominant or even stable instant messaging platform today.

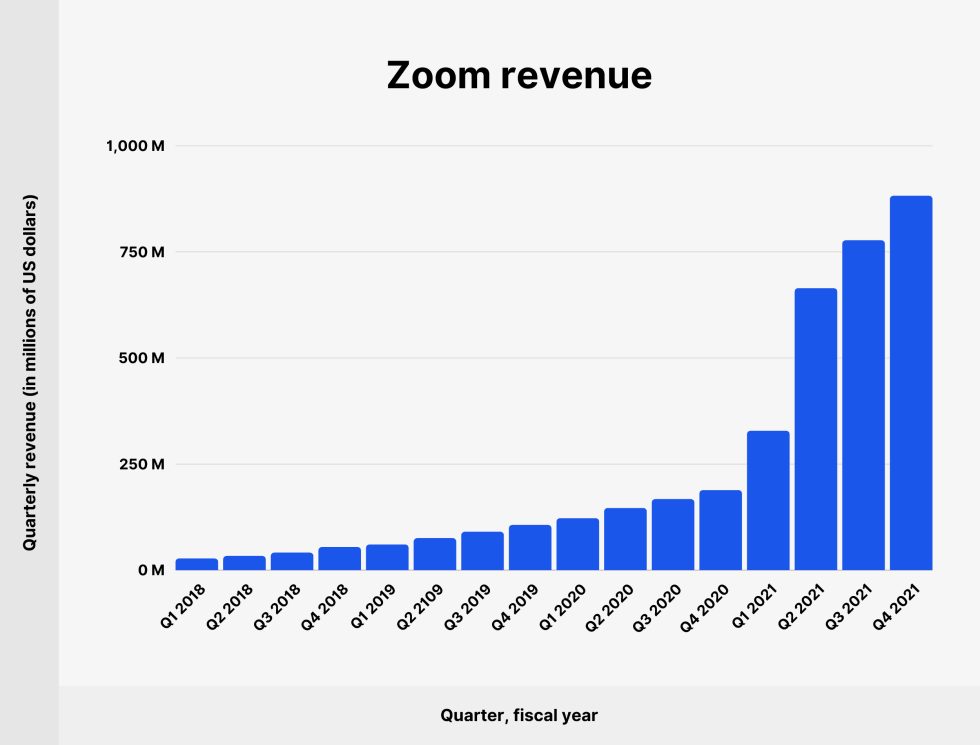

Google’s 16 years of messenger wheel-spinning has allowed products from more focused companies to pass it by. Embarrassingly, nearly all of these products are much younger than Google’s messaging efforts. Consider competitors like WhatsApp (12 years old), Facebook Messenger (nine years old), iMessage (nine years old), and Slack (eight years old)—Google Talk even had video chat four years before Zoom was a thing.

Currently, you would probably rank Google’s offerings behind every other big-tech competitor. A lack of any kind of top-down messaging leadership at Google has led to a decade and a half of messaging purgatory, with Google both unable to leave the space altogether and unable to commit to a single product. While companies like Facebook and Salesforce invest tens of billions of dollars into a lone messaging app, Google seems content only to spin up an innumerable number of under-funded, unstable side projects led by job-hopping project managers. There have been periods when Google briefly produced a good messaging solution, but the constant shutdowns, focus-shifting, and sabotage of established products have stopped Google from carrying much of these user bases—or user goodwill—forward into the present day.

Because no single company has ever failed at something this badly, for this long, with this many different products (and because it has barely been a month since the rollout of Google Chat), the time has come to outline the history of Google messaging. Prepare yourselves, dear readers, for a non-stop rollercoaster of new product launches, neglected established products, unexpected shut-downs, and legions of confused, frustrated, and exiled users.

Table of Contents

- Google Talk (2005)—Google’s first chat service, built on open protocols

- Google Talk ran Android’s entire push notification system

- The slow death of GTalk

- Google Voice (2009)—SMS and Phone calls get a dose of the Internet

- Google Wave (2009)—An email killer from the future

- Nobody knew what Wave was for or how to use it

- Google Buzz (2010)—The non-consensual social network

- Slide’s Disco (2011)—An independent app escapes the Googleplex

- The Google+ Era (2011)—Google’s social panic

- Google+ Hangouts video chat—The first Hangouts

- Google+ Huddle/Messenger—I guess we should have some kind of DM function

- A competitor emerges—iMessage has entered the chat

- One more competitor—WhatsApp is now worth $22 billion

- Google Docs Editor Chat (2013)—Just like Gmail chat, but not integrated with anything

- Google Hangouts (2013)—Google’s greatest messaging service

- The death of Hangouts, unified Google messaging, and hope

- Google Spaces (2016)—A messaging app for Google I/O 2016 attendees

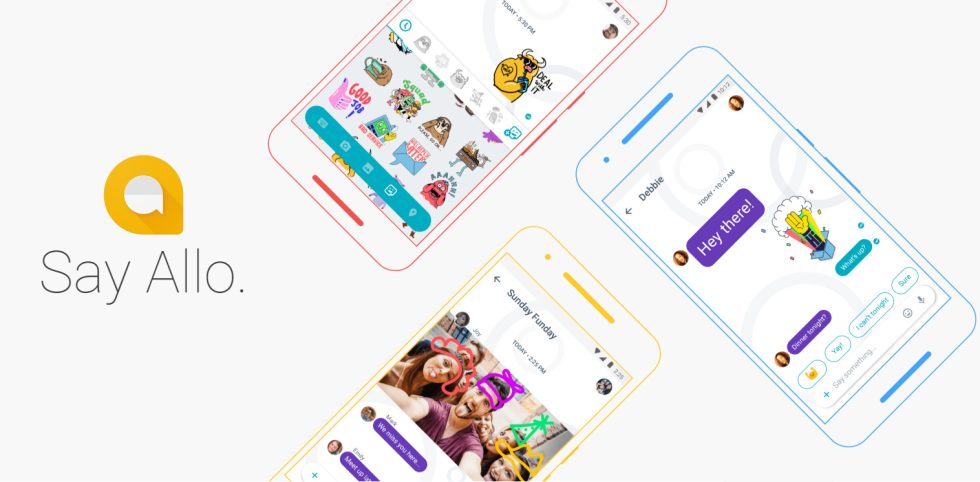

- Google Allo (2016)—Google’s dead-on-arrival WhatsApp clone

- Allo’s legacy: The Google Assistant

- Google Duo (2016)—A video companion app for… WhatsApp?

- Google (Hangouts) Meet (2017)—Not Zoom

- YouTube Messages (2017)—Yes, this was really a thing

- Google (Hangouts) Chat (2018)—Part 1: Cloning Slack is actually a good idea

- Google Maps Messages (2018)—Business messaging, now with the instability of Google

- Google & RCS (2019)—So we found this dusty old messaging standard in a closet…

- RCS is bad, and anyone who likes it should feel bad

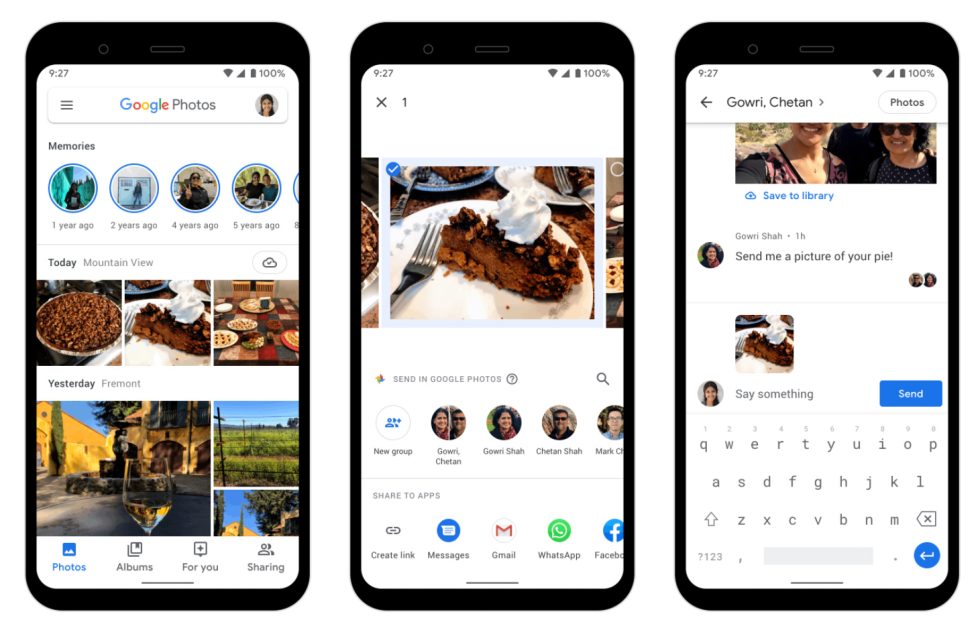

- Google Photos Messages (2019)—You get a messaging feature! And YOU! And you!

- Google Stadia Messages (2020)—Two great tastes that taste great together

- Google Pay Messages (2021)—We actually learned nothing from Google Allo

- Google Assistant Messages (2021)—Text and voice chat, for families?

- Google Phone Messaging (2021)—Isn’t this going a little too far?

- Google Chat, Part 2 (2021)—No wait, this is actually a consumer app now!

- Is anyone in charge at Google?

Google Talk (2005)—Google’s first chat service, built on open protocols

Lifetime: August 24, 2005-June 26, 2017 (12 years, until a Hangouts merger in 2013)

Clients: Windows, Android, the web, Gmail, Blackberry, iPhone, iGoogle, Orkut, any XMPP client

In the beginning, there was Google Talk, and things were good. Google’s first messaging service (which often got the unofficial nickname „GChat“) was also one of its best. It boasted a wide range of platform support, a long shelf life, and useful integration in a number of other Google products. Google Talk was part of the second big wave of popular instant messaging apps, and it seemed primed to take on the 1990’s stalwarts of instant messaging like AOL Instant Messenger (AIM), ICQ, Yahoo Messenger, and Windows Live Messenger.

So much about Google Talk’s life and design sounds like it was created by a totally different company from the Google that exists today. The original vision for Google Talk was about openness and „enabling user choice.“ Google wanted instant messaging to work like email, where different service providers and clients could all talk to each other over a single standard (wouldn’t that have been nice?). That standard was XMPP, or the „Extensible Messaging and Presence Protocol,“ an open source communication protocol used for passing around chat messages, presence information, contacts, and more. Google pledged to federate (or allow cross-communication) with any other chat service supporting the standard. You could also punch the right settings into any XMPP-compatible third-party client and talk to your Google Talk friends.

Because Ars Technica is a Very Old Website, you can still read a day-one, 2005 Google Talk review right here from Ars Editor-in-Chief Ken Fisher (can you believe Ken used to write articles?). Back then, Ken called day-one Google Talk „the Stone Age of instant messaging,“ citing a severe lack of features like file sharing, chat logs, group chat, or emoticons. There was one supported platform at launch: Microsoft Windows. That was mostly fine in 2005 when Windows had something like a 97 percent market share. Even then, XMPP support meant that you could still get online with the other 3 percent of operating systems by using a ton of third-party clients.

There will be a few recurring themes in this exhaustive history, and one of them is Google’s penchant for launching things in a „Minimum Viable Product“ (MVP) state. MVP is Silicon Valley project manager lingo for launching with the absolute bare minimum of features, getting feedback from the public quickly, and letting that feedback determine the future of the product. The idea is that it’s cheaper, easier, and less risky than developing a fully featured product in a bubble, since such a product might miss the mark with the public despite all the work. The downside to an MVP launch is that your product gets the most attention and news coverage when it is brand new, and you’re often giving a bad first impression. In a competitive landscape, there’s a chance the public will check out your bare-bones creation, declare it to be hopeless, and forget about it.

Google does MVP launches all the time, and with Google Talk, that meant launching with the ability to send messages, do voice chat, and little else. Later we’ll cover some of Google’s dead-on-arrival MVP launches, but 2005 was a different era. Many people saw Google Talk’s bare-bones interface and features as a positive thing. In the era of AOL Instant Messenger, IM clients were noisy, flashy billboards with a million features and dedicated UI space for banner ads. A 2006 post from the Google Operating System blog sums up the differences well with installer file sizes, which is an interesting benchmark metric. Yahoo Messenger was 9.5MB. Windows Live Messenger was 15.3MB. Google Talk was a lean, mean 1.45MB.

While the AOL-style kitchen sink design was horrible, it also solved a key problem that will hang over Google’s efforts: „How does a messaging service make money?“ Back in the AIM days, that was answered with a literal banner ad in the UI. Every AOL user was generating ad impressions and revenue every time they used the service. Google Talk’s removal of the banner ad was a breath of fresh air, but it also meant the product had no plan for making money. The vast majority of Google’s messaging apps have nothing to offer when it comes to the monetization question. Maybe that’s a big part of why we’re here.

While Google Talk launched as a basic product, once it was out the door, a series of rapid-fire updates followed. In December, Google bought a 5 percent stake in AOL for $1 billion and promised a cross-communication between AIM, ICQ, and Google Talk. January 2006 saw the first official mobile client: a Blackberry app (Android did not exist yet) and federation with the public XMPP network. In February, Google Talk became integrated with Gmail on the web and added chat logs. Avatar support came in March, and July brought file transfers, voicemail, and sharing music status. September opened up Google Talk to non „Gmail accounts“ (this pre-dates unified Google accounts), and November added integration with Orkut, a social network the company launched two years earlier. By the end of the year, Google announced plans for integration with traditional phone systems, letting you dial a phone number from your computer.

The Gmail integration at around the six-month mark was a big deal for Google Talk. Chat contacts got a spot in the Gmail sidebar, and chat messages would appear as pop-up windows alongside your email. As Google put it in its blog post, „Gmail is now just another XMPP client that connects to the Google Talk network.“ If Gmail users didn’t check out Google Talk when it first launched or gave up on it after trying the bare-bones launch, they would definitely be reminded of it now that it got a headline spot in the Gmail interface.

A lot of Google’s future instant messaging decisions seem to be about recapturing the magic of Google Talk, and it seems like one of the lessons learned was „leverage the rest of the Google user base to shove your new product in front of users.“ Like with MVP launches, this strategy would fail spectacularly in the future, but it worked out for Google Talk. Web-based IM was novel in 2006, and casting a slightly wider net with Gmail from „email“ to „communication“ made sense. Gmail integration also brought with it chat logging, via a searchable, cloud-stored „chat“ label in Gmail. Being able to dig through all your email and chats with a single search was great.

That was basically the first year of Google Talk’s existence, and the overwhelming feeling at the time was „optimism.“ While the original MVP release could have turned off some users, Google quickly addressed complaints with the original release, and Talk felt like a growing instant messaging service with a bright future and lots of resources behind it. Plus, it was from Google. In the 2005-era, Google was a rocketship. This was a company that recently disrupted the web email market with the launch of Gmail and its astounding 1GB of free online storage. Google Maps had just arrived with the revolutionary ability to move the map around without having to reload the entire website. Google had just had an IPO! This was a company that was regularly up-ending existing markets, and now the company was going to be a dominant force in the instant messaging market, right?

Many of Google Talk’s clients were for things you’ve probably forgotten about. A client for the „iGoogle“ customizable homepage arrived in 2007, along with a standalone web client at Google.com/talk. Today, Google developing a single native Windows app sounds crazy, but in 2008, a second Windows client called the „Google Talk Labs Edition“ just threw the web edition of Google Talk into a Win32 WebKit box, complete with support for notifications. Google really started to neglect the native Windows client once this launched, making the Labs Edition—basically the web edition—the premiere version.

In 2008, Google Talk arrived on the iPhone via—who remembers this?—a mobile web app! While the iPhone launched in 2007, the native iPhone app store did not launch until later in 2008, and developers were limited to web apps made for Safari.

2008 also would mark Google’s first foray into video chat, first with Google Talk in Gmail and later in the main client. A side project from all this messaging research will be „Google is also terrible at video chat.“ While this video iteration wasn’t yet the group video chat solution that Google is still scrambling to get together in the coronavirus age, Google’s video chat ambitions actually started 12 years ago.

Google Talk’s voice and video chat required a browser plugin. It ran on technology from a company called „Global IP Solution (GIPS),“ which sold VoIP engines to companies like Google, AOL, Yahoo, Oracle, and WebEx. In 2010, Google decided it relied enough on the company and bought GIPS for $68 million. A year later, Google open-sourced GIPS’s technology and IP, giving birth to the WebRTC project. Today, WebRTC is the dominant VoIP technology and a W3C standard, allowing most web browsers to make a voice or video call with zero plugins.

Google Talk ran Android’s entire push notification system

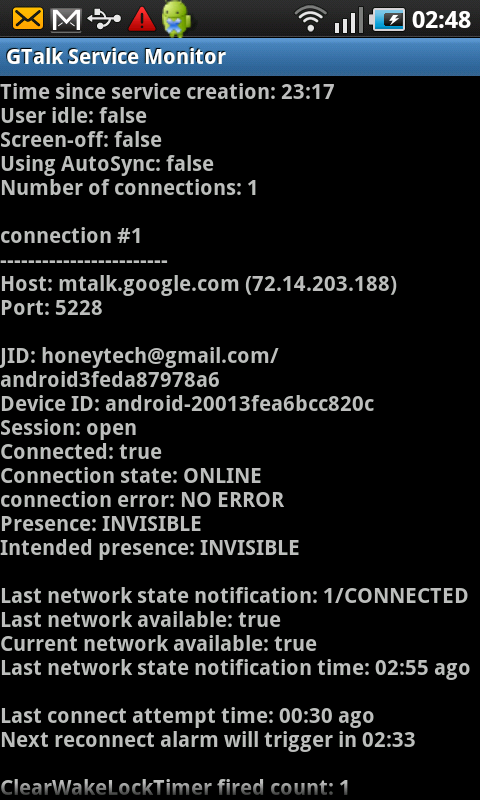

By 2008, a little operating system called „Android“ came out of the Googleplex. BBM—Blackberry Messenger—had launched a few years earlier and was a valued feature of Blackberry phones, and so the Android Team became big fans of Google Talk, which it could use as a BBM fighter. The team shipped an original client along with Android 1.0 and added video chat support in 2011. Android didn’t just support Google Talk, though; it was actually a core feature of the operating system. Android’s entire cloud messaging system runs on XMPP, and, in the beginning at least, it was the same always-on Google connection as your Google Talk account. In fact, for a long time, Android’s background process for all push notifications and syncing was called „GTalkService.“

GTalkService ran communication for Android’s entire push notification system, meaning that even things like a new Gmail notification came blasting down an always-on chat session between you and Google. XMPP was a real-time, authenticated way to quickly pass messages back and forth, so Google built an OS-wide notification system around it. The early days of Android development were done at a break-neck pace to try to catch up to the iPhone, and messy decisions like merging push notifications with your in-house messaging service helped get there faster.

Google eventually opened up the push system to third parties, first with Android „Cloud to Device Messaging,“ then „Google Cloud Messaging,“ and then „Firebase Cloud Messaging.“ (If you haven’t noticed, Google likes to reboot and rename products.) The modern Firebase Cloud Messaging is actually still XMPP-based to this day, though. Of course, it has been separated from Google Talk now.

I am just going to go ahead and call GTalkService the early ancestor of Google Play Services. GTalkService wasn’t only used for notifications on Android—the cloud synchronization of Google account data also ran through the GTalkService, keeping things like your contacts and calendar events up to date. GTalkService was even used to install apps on Android. The co-founder of Duo Security, Jon Oberheide, has two fantastic writeups on GTalkService from 2010. As he explains, „When you click to install an app through the Android Market, Google pushes down an INSTALL_ASSET to your phone [over GtalkService] which causes it to fetch and install that application.“ You didn’t actually request the app package from the Android app store, they were pushed to your phone via Google Talk. (Did I mention early Android development was quick and dirty?)

The benefit of doing app install calls over push notifications is that you don’t actually have to be in front of your phone to install an app. Google surfaced this feature with the Android Market (now Play Store) website, where you could remotely install a phone app from your desktop web browser—it’s all the same push request. GTalkService even gives Google a nuclear option for malware. The company could remotely uninstall malicious apps from your phone, without your permission! Oberheide holds the distinction of being the first person to trigger a remote, mass uninstall after uploading a (harmless) malware proof-of-concept app to the Android Market in 2010. After unveiling its malware nuke to the world, Google warned: „While we hope to not have to use it, we know that we have the capability to take swift action on behalf of users’ safety when needed.“

The slow death of GTalk

After maybe 2009, not much happened with Google Talk. The Android team kept building mobile clients up until 2011, but it seemed like the original team lost interest in the service. This is how it always works with Google chat services. The ones that don’t get shut down eventually are abandoned and left to rot. Users get frustrated with the lack of continual development and old clients and slowly migrate to other services. Eventually, a new Google team comes along with plans to reboot everything.

The shutdown of Google Talk was a very slow transition, and with the plethora of clients, the merger with Google Hangouts, and third-party XMPP support, it’s hard to pick an exact time of death. But the beginning of the end for Google Talk was in 2013 with the release of the Hangouts chat service we know today. Hangouts wasn’t just another messaging app, it was a replacement for Google Talk, allowing you to carry your contacts and messages to the new service. Some clients, like the Android Google Talk app, got an in-place automatic upgrade to Google Hangouts, along with optional transitions and replacements for most clients. The first major client shutdown came two years later when the Google Talk Windows client officially stopped accepting logins on February 23, 2015.

If you really wanted to go down with the ship, the last gasp for Google Talk was surprisingly late: June 26, 2017. At that point, third-party XMPP connections to the Google Talk service stopped working, the Gmail web integration was forcefully transitioned to Hangouts, and (if you had somehow dodged Android app updates for four continuous years) the legacy Google Talk app also stopped working. Google Talk had long become irrelevant with the rise of Hangouts in 2013, but if you wanted to pick a final death date, June 2017 is it. RIP Google Talk.

Part of the reason for the lengthy shutdown is that it wasn’t just „Google Talk: the consumer chat service“ that Google was turning off. It was also „Google Talk: The back end XMPP Google service“ that Google needed to make sure kept running, which by now had wound its tendrils into several services. Google Talk needed to be killed without interrupting service for Firebase Cloud Messaging, which grew out of the XMPP project. Google Docs actually had a bit of a service interruption when Google Talk finally shut down in 2017, too. While it was never cross-compatible with Google Talk, it turns out those pop-up chat boxes were actually based on Google Talk originally. A GSuite blog post in 2017 mentioned that, because „Docs Editors chat functionality is built on Google Talk,“ work needed to be done to „decouple the feature from Talk“ when it shut down. G Suite organizations that didn’t get their transitional Google Talk and Google Hangouts settings correct would briefly lose chat functionality.

Google really doesn’t do product shutdowns like this anymore: shutdowns where you had a lengthy four-year shutdown period and not just a relatively smooth transition to a new service but a fully optional transition that lasted several years. Today, the company is simply a lot more ruthless about kicking users off a service and abandoning them.

Google Talk got a really long section in this history, but it deserves it. As Google’s first and one of its most successful instant messaging services, it set the blueprint for everything that followed. If you pay attention, you’ll see future Google messaging services poorly try to copy Google Talk’s homework, often with disastrous results. When you’re the OG Google chat service, you’re adding new features that didn’t exist before for Google users. When you’re everything that comes after Google Talk, people are just asking, „How is this better than Google Talk?“

Google Voice (2009)—SMS and Phone calls get a dose of the Internet

Lifetime: March 11, 2009—Present

Clients: web, Android, iPhone, Web OS, Blackberry

It only took 3.5 years after the launch of Google Talk for a second Google messaging service to appear, though it actually had a good argument for why it should exist alongside Google Talk. In March 2009, Google asked the question: „What if we rigged up the phone system to the Internet?“ and Google Voice was born. Instead of a landline phone number or a cell phone number, Google Voice gave users a Google phone number—with an area code and everything—that was device agnostic. Your phone calls could be forwarded to other phone numbers based on the time or contact, and your text messages were accessible via the web and various apps.

The best part of Google Voice is having a number that really feels like you own it. In the early days of Google Voice, carriers made number porting as annoying as possible, and switching cell providers could mean losing your carrier-owned phone number. With Google Voice, it didn’t matter. You could give everyone your Google Voice number, and switching services just meant adding a new forwarding number that you never told anyone about.

The origins of Google Voice actually started back in 2007 when Google acquired GrandCentral Communications. GrandCentral was where all of Google Voice’s phone call (as opposed to messaging) functionality came from. It offered a new phone number with forwarding to other lines and an audio-only voicemail box that was accessible over the Internet. There wasn’t any texting functionality, though.

With the launch of Google Voice, Google added a ton of features to GrandCentral, like SMS support, conference calling, and low-cost international calling. The Googliest feature was voicemail transcription, where Google’s voice recognition AI would (attempt to) transcribe your voicemail into easily scannable text. In the early days, it wasn’t super accurate, but Voicemail transcription was still better than the black box of a play button. There was usually enough wonky text information to figure out if the voicemail was important or not. Voicemail transcription was one of Google’s first voice recognition products, and in the early days, Google Voice’s „creative“ interpretations of voicemail audio gave rise to the meme of sharing failed and funny Google Voice transcript errors. Take a look; Google’s speech-to-text technology has come a long way.

We’re here for the texting part of Google Voice, though, and SMSes to your Google Voice number worked just like a texting app. These showed up anywhere you had the app installed or on the web instead of being siloed on your phone. Since Google Voice was SMS, there were basically no features. Even getting MMS support was a long-running battle: it first showed up for Sprint users (via email) in 2011, but proper MMS support on all carriers didn’t arrive until 2017. Voice was never a flashy service, but since Google Voice was SMS, it let you talk with anyone, and it let you pull your dumb cell phone number into the cloud where it could work on multiple devices.

Voice was seen as a threat to carriers at the time, so the service ruffled a few feathers when it came out. When Google submitted an official Google Voice app to Apple’s app store, Apple rejected Google’s app and removed a few third-party Google Voice apps it had previously approved. This move drew the ire of the FCC, and it questioned Apple’s exclusive carrier partner at the time (in the US): AT&T. With free VoIP calls, SMS, and voicemails, Google Voice was an obvious threat to AT&T, which previously had been against VoIP apps on the iPhone. AT&T told the FCC it was not involved, however. Google said Apple VP Phil Schiller personally blocked the app, saying Apple didn’t want apps that „duplicated the core dialer functionality of the iPhone.“ Apple said it had not, in fact, rejected the Google Voice app, and it was still „studying“ the app. The Google Voice iPhone app was initially submitted in June 2009, and by the time of the FCC inquiry, the Google Voice app had been delayed for two months. Apple must have been doing a marathon study session!

Apple’s „studying“ continued for the entirety of 2009, and by January 2010 Google had launched a Google Voice mobile web app for iPhone and Palm’s WebOS (may it rest in peace). Apple ruled over the App Store with an iron fist, but it couldn’t stop the Internet, and Apple users could point their browser at the Google Voice mobile site and make calls, view voicemail, or send SMS all through a web page. The downside was that the web couldn’t do notifications at the time, so Google Voice didn’t really work well for receiving SMSes or voicemails. It wasn’t until November 2010 that Apple finally finished its meticulous study session and let Google Voice into the app store.

Google Voice is the first item on our list that is actually still around; every day that Google Voice continues to exist feels like a surprise. The service has been hanging around for 11 years now and has spent most of its life in the „neglect“ stage of a Google messaging service. It often feels like Google Voice exists in a dusty closet at Google HQ somewhere, and the company forgets about it for years at a time.

Besides seeing its share of neglect, Google Voice has also seen its share of shutdowns. Google Voice used to have a range of third-party apps, but Google killed them all in a single swing one day in 2014. The company declared that any third-party apps that worked with Google Voice phone calls or SMS—which, by the way, had been operating for years—were „unauthorized,“ „a threat to your security,“ and „violating the terms of service.“ Google didn’t want to allow third-party Voice apps but also didn’t want to develop the first-party app itself, so it left users stuck with the crappy, neglected app.

We’ve already talked about how Google Talk and the Android push notifications were built around XMPP, but would you believe Google Voice at one point also used XMPP? XMPP was used to connect calls, and with this open standard, users could rig up landline phones to work directly over the Google Voice system, making it a VoIP provider. You’d also get free voice calls. XMPP support was shut down in 2018, but it sounds like it was replaced with some kind of closed-off solution that can be licensed by some companies. Polycom, for instance, still makes Google Voice FXO VoIP Gateways.

Google Voice has seen a resurgence starting around the launch of Google Fi in 2015, which merged the Google Voice feature set with an MVNO service. The two services were so similar at launch that you couldn’t even have both a Google Fi number and a Google Voice number—you had to port your Voice number to Google Fi. Since then we’ve seen a renewed commitment to Google Voice from Google, with revamped apps launching in 2017. Google Voice became a part of GSuite in 2018 and got mobile VoIP calls in 2019.

Google Wave (2009)—An email killer from the future

Lifetime: May 28, 2009—January 31, 2012 (2 years, 8 months but declared dead August 4, 2010)

Platforms: The web

I personally believe that Google Wave does not belong on a list of messaging apps, but every time I leave it out of a messaging app discussion I inevitably get comments saying, „I can’t believe you forgot Google Wave!“ To stop those, it’s this exercise’s policy to cast a wide net and cover borderline products, at the very least so we can formally define them as „not a messaging app.“ Thus, Wave makes the cut.

For the record: Google Wave was email, not a messaging app. It wasn’t really used for one-to-one communication, and at no point was it possible to deliver notifications to a phone. At Google I/O 2009, Google introduced Wave to the world specifically as an email alternative, with co-creator Lars Rasmussen saying „Email was invented over 40 years ago…what might email look like if it was invented today?“ At no point was Wave out to replace Google Talk.

On the desktop, Wave had three main columns: a navigation and contact column on the right, an inbox in the middle, and a message view on the right. Like email, Wave would let you create message threads, and users could reply to either an entire group or a single person. Because Wave was hosted content and not email text that was copied to local computers, contact selection worked more like a modern permission system or chat room. You could grant or remove access to Wave threads by adding or removing people.

Wave was the first Google product to do real-time, letter-by-letter communication. The service would instantly send each keystroke across the Internet, and it would show up on another person’s screen, all through the magic of HTML5. Active Wave threads looked alive, with replies popping up, and images being uploaded in real time, letter by letter, without refreshing the page. Wave even had a feature called „Playback“ where the entire Wave creation process could be played back (in chunks) from scratch.

The live typing, letter-by-letter technology was eventually brought to Google Docs, which is where most people encounter this sensation today. The Wave team actually demoed collaborative document creation in a Wave, complete with in-line comments. Wave’s input system was really the basis for the modern version of Google Docs, and the entire document system was deemed good enough to be ported over.

Wave was created by Lars and Jens Rasmussen, the same pair of brothers who brought the world Google Maps. In the same way that Google Maps‘ live, scrollable map was a revolution for browsers at the time, Wave’s live typing and other app-like features were cutting-edge stuff at the time (though an app called EtherPad, which Google later acquired, cracked live typing first). The I/O 2009 intro to Wave felt like it was from another era. „[Wave] is an unbelievable, powerful demonstration of what is possible in the browser,“ Engineering VP Vic Gundotra told the crowd. „Over the next hour and a half, as you see this product, you. will. forget. that you are looking at the browser. I want you to repeat after me: I am looking at an HTML5 app. I am looking at what’s possible in the browser.“ Hearing this again is wild. Remember when browser apps sucked?

Another „you can do that in a browser?!“ feature of Wave was the ability to upload photos with drag-and-drop, just like in a native app. This was the one ability of Wave that wasn’t purely HTML5 wizardry. It required the installation of Google Gears, Google’s browser API shim, at launch. Google said it was working to make drag and drop from the desktop part of the browser standard, and the feature eventually made it into Chrome in 2010.

While Google Wave was the first implementation of Wave, Google did not try to make itself the center of Wave or to build a walled garden. Wave was open source, and like Google Talk, Google imagined Wave as a federated platform where users on different clients and service providers could still talk to each other. The Wave Federation Protocol happened over—wait for it—XMPP, with the extra Wave bits implemented as an open extension to the XMPP core.

Wave had a heavy branch of features dedicated to APIs and bots. Waves could be embedded in blogger webpages, allowing for live edits and additions to show up on a normal web page. Wave communicated this by adding a „Blogger“ bot to a Wave, letting everyone know the information was public and keeping the embedded Wave in sync (letter by letter, in real time) with the main Wave. Some bots could do things like import tweets into a Wave or play games or do real-time translation.

I can see the confusion people have in calling Wave a messaging app. Email and messaging are both just text, so a real-time email app is just as „instant“ as an instant messaging app. The difference is in the interface, though. Wave was always a big, heavy, inbox-driven app that you were supposed to live in, making it very email-like. Wave never got any mobile apps and only supported a single platform: the browser. That meant there was a mobile version of the site, but especially in 2009, this was an awful experience. Even if you wanted to use Wave as a messaging service, without an app, you wouldn’t be able to make your phone beep about an incoming message. Therefore, it has to be disqualified from being deemed „messaging.“

Nobody knew what Wave was for or how to use it

Google announced the death of Wave on August 4, 2010, just 15 months after the service was announced. Google said flatly, „Wave has not seen the user adoption we would have liked.“ Wave became read-only on January 31, 2012, and all Wave content was deleted in April 2012. As an open source project, Wave was supposed to live on at the Apache Software Foundation, but the project never produced an official release, and it was retired in 2018.

A big contributor to Wave’s death was the lack of a network effect. Wave could only be used to communicate with other users on Wave, so you get the catch-22 of people only wanting to use Wave if people already used Wave. Exacerbating this problem was the fact that Google hamstrung the initial Wave userbase with an invite system, so even interested users couldn’t try out the service immediately. (Admittedly, a load of users firing up the all-live, all-the-time app was probably a scary proposition for Google’s network engineers.) Wave went a whole year before removing the invite system, which, for a collaborative communication app, seriously limited its viability. On May 26, 2010 (Google I/O 2010), Wave’s invite system was dropped, and it was open to the public. But by then, the hype was gone and no one cared. Wave lasted an incredible 70 days as a public service before Google announced it was dead.

Shortly after Wave’s death, a group of Ars staffers got together and rounded up a litany of complaints covering why they didn’t use the service. This was before the browser javascript benchmark wars, and browsers weren’t great at handling the javascript-heavy Wave site, which was described as „slow and wonky.“ The triple-plane layout could get cramped on a 4:3 desktop monitor (though columns were minimizable), and the site was called „ugly“ and „confusing.“ Spotting the newest messages, which could be anywhere in a long Wave, was difficult. Like a wiki, ownership of an individual message on Wave was not really a thing. Anyone could edit, or delete, anyone else’s content in the Wave.

Live, letter-by-letter typing is an interesting communication method, and if you’ve never tried, fire up Google Docs with a friend and give the document text a shot as a communication platform. For good typists, it’s a faster, more fluid form of communication that’s kind of fun. For less confident typers, live typing turns keyboard input into a high-pressure performative act with a live audience, and you can see how it would turn off some people. The lack of any kind of draft mode meant you didn’t have a free second to compose your thoughts into text or think about what you wanted to type—every letter was immediately broadcast onto the Internet, showing the world your typing speed and error rate. Google is a place full of tech-savvy computer nerds, and sometimes a group like that, building a product in a bubble, completely whiffs on the emotional human element of a messaging app or social network. This was one of those times.

Wave policy of „always live update everything, all the time“ can lead to a Wave inbox being pretty overwhelming when it is active and popular. Martin Seibert made the above video for a Techcrunch article showing just how bad it can get. Being live means the inbox just constantly jumps around as new messages load in, making it difficult to even read a thread subject before it disappears. When popular, Wave was a completely unmanageable mess where you’d never hit Inbox zero.

When Wave was still active, there was a ton of talk about federation, bots, and APIs. Users constantly hoped that someone, Google or a third party, would make Wave interoperable with any other service, like Google Talk or email. That approach would solve the problem of Wave only being useful when talking to Wave users. If Wave hooked up to another service, Wave could be useful for the individual user no matter what, and Wave features could be added any time two Wave users were communicating with each other. Google Voice did a great job of this with the phone system by adding extra features to SMS, Voicemails, and phone calls. A solid connection to an established communication network never materialized, though, so Wave never had a solid userbase.

In the peak social media days, everyone was on Facebook because everyone was on Facebook. In this case, nobody used Wave because nobody used Wave. From here on out, the network effect would forever be a huge problem for Google messaging services. Some future projects took note of this and tried to juice the initial network—in some successful and, uh, extremely unsuccessful ways. Speaking of which…

Google Buzz (2010)—The non-consensual social network

Lifetime: February 9, 2010—December 15, 2011 (1 year, 10 months)

Platforms: Desktop Gmail, mobile web apps for Android and iOS.

Where do you even start with Google Buzz, one of Google’s most notorious products? Remember that in 2005, Google Talk found a major shortcut to a big user base when it was integrated into Gmail. So, surely, the same strategy would work for Google’s social network aspirations, right? In early 2010, the Google Buzz social network launched, not as a standalone service but as a Gmail sidebar component just like Google Talk. Oh yeah, it also started automatically following and sharing stuff with your frequent email contacts without really asking users if that was OK. What followed was a whirlwind of controversy, complaints, and lawsuits, and it’s kind of astounding how most of the Google Buzz saga took place over just four days.

Google built a basic social networking app with a scrolling list of posts and replies—it was basically identical to Facebook or Twitter, but in Gmail. Follow a person. Post some text. Add a picture. Press the „like“ button. The basics were wholly unoriginal other than the fact that it was invading your email inbox.

Every single design decision made for Google Buzz can be framed as „fixing the network effect.“ Remember how Wave died because nobody used Wave? That was not going to happen with Google Buzz. Shoving the product into Gmail would quickly get it a big user base of its own. Buzz was also pitched as a „social aggregator“ and could pull in posts from other services, so even if none of your friends were on Buzz, you could still use Buzz and see their content. Buzz would pull in posts from Twitter, photos from Picasa and Flickr, or (brace yourself for sadness) articles you liked on Google Reader.

Buzz’s critical mistake was how the initial setup worked. It was totally automatic—Buzz built your social graph for you by automatically adding frequent contacts from Google Talk and Gmail. You would automatically follow them and they would automatically follow you, all without the input of a human on either end. It also automatically connected Google Reader and Google Picasa data and instantly associated any public content with your Buzz profile. From there, the service shoved all that in front of any „friends“ it detected.

Google’s day-one blog post for Google Buzz is worth a read just to get an idea of what an astoundingly out-of-touch, non-consensual nightmare the Google Buzz rollout was. „Buzz is built right into Gmail, so there’s nothing to set up,“ the blog post reads. „You’re automatically following the people you email and chat with the most.“ Buzz was also going to spam the hell out of your inbox unless you found a way to stop it: „To make sure you don’t miss out on the best part of sharing, Buzz sends responses to your posts straight to your inbox. Unlike static email messages, Buzz messages in your inbox are live conversations where comments appear in real-time.“ Google just decided to turn your email client into a social media network, and it hoped you were OK with that. Nobody was.

Buzz never got a standalone website, and it never got any mobile apps. It did get a mobile website for Android and iOS, via a coveted link on the mobile Google.com search page. Android 2.0 also integrated a Google Buzz home screen widget and Google Maps added a „buzz about this place“ button in location listings. Besides the expected mobile browsing of, uh, buzzes, mobile Buzz was also a Foursquare and Dodgeball clone, letting you tag posts with a location.

Google Buzz’s automatic setup exposed a ton of data about people without really properly informing them or getting their consent. Like most social networks, who your friends are following was public information on Buzz, but since this was created automatically from contacts, Buzz exposed everyone’s frequent email contacts to the world. Your Buzz username was also your email address, so that was automatically exposed to the world, too. If you used the Foursquare-like location sharing, then your location would be broadcasted to any „nearby“ Buzz users—not just your friends.

Buzz used a lot of the same predatory privacy tactics as Facebook, where, sure, there were technically controls for all this stuff somewhere, but they were purposefully deemphasized to trick users into making everything public. Buzz made users opt-out of exposing sensitive information, instead of having them opt-in to sharing. Users who didn’t carefully comb every square inch of the screen for the low-contrast fine print didn’t understand what they were exposing, and they felt betrayed after realizing what was shared with their contacts.

By day two, Google still wasn’t in touch with the reality of what it had done. A new blog post touted how proud Google was of all the (forced) usage Google Buzz was getting. „It’s been just two days since we first launched Google Buzz. Since then, tens of millions of people have checked Buzz out, creating over 9 million posts and comments,“ the post stated. „Plus, we’re seeing over 200 posts per minute from mobile phones around the world.“ If you’re a bean-counting, spreadsheet-obsessed, emotionless robot, this probably sounds like a success. The problem was, no normal human liked this, and most of these posts were complaints. Google’s day-two blog post gave a minor nod to some privacy concerns people had raised, but the damage was already done.

The rest of the world had turned against Buzz by day two, and the consumer revolt was incredible. Buzz was called a „privacy nightmare“ in the press. In one viral post, a woman recounted how Google Buzz’s algorithms decided it was a good idea to automatically reconnect her with her abusive ex-husband and threatened her safety.

By day four, Google finally gave up and posted an apology on its official blog. „We quickly realized that we didn’t get everything quite right,“ the company said. „We’re very sorry for the concern we’ve caused and have been working hard ever since to improve things based on your feedback.“ These „improvements“ involved stripping back Buzz’s automatic setup process and turning „automatic following“ into a „suggested contacts“ list. The company added better blocking controls for unwanted followers and stopped auto-connecting Picasa photos and Reader articles. It also added the option to turn off Google Buzz in the Gmail settings, finally providing an opt-out for Buzz entirely.

As far as much of the public was concerned, the entire life and death of Google Buzz occurred these first four days. Buzz launched, it messed up everyone’s Gmail for a few days, and everyone scrambled to turn it off and clean up the mess Google had made. Buzz was never anything special in terms of the actual product, and the stigma of the initial launch and the out-of-place Gmail integration made most people ignore it or turn it off.

Beyond week one, Buzz’s lasting legacy centers on lawsuits and legal action. The Electronic Privacy Information Center (EPIC), a privacy watchdog and public interest research group, filed an FTC complaint over Buzz’s privacy violations. After an investigation, Google settled with the FTC, committing to maintaining a „comprehensive privacy program“ for 20 years. A class-action lawsuit was filed that eventually saw Google settle for $8.5 million. Google Buzz even earned international condemnation, with government officials from 10 countries sending Google an open letter telling it to drop its „launch now, fix later“ policy.

Buzz feels like something that was generated entirely by an algorithm. Any normally functioning human would understand that there is a difference between email and social media and what those two things are used for. Email is often an obligatory, formal, and official form of communication with people and companies; social media is for fun (theoretically). There are tons of accounts you would communicate with over email that you would never want to see on social media, and vice versa, yet no one at Google realized this during the making of Google Buzz.

Buzz’s death was announced unceremoniously as the second bullet point in one of Google’s infamous „spring cleaning“ posts on October 14, 2011. At this point, absolutely nobody cared, since all of Google’s social attention had been on its new baby, Google+ (that had launched four months earlier). Google announced Buzz would be shut down in „a few weeks“ and that it „learned a lot from products like Buzz, and are putting that learning to work every day in our vision for products like Google+.“ I can’t find any reports of the actual Google Buzz shutdown date, but the Wikipedia entry has a completely unsourced date of December 15. If accurate, that would mean the product lasted one year and one month. Really, though, Google Buzz was four days of terror and then it died.

Slide’s Disco (2011)—An independent app escapes the Googleplex

Lifetime: March 24, 2011 to October 11, 2012 (1 year, 6 months)

Platforms: iOS, Android, the web

Is this one new for you? This one is new for me. Once upon a time, there was a company called „Slide, Inc.“ It was founded in 2004 by PayPal co-founder Max Levchin, and this company was the maintainer of the super-popular Facebook games Superpoke and Superpoke Pets. One day, Google—probably as part of its panic over the rise of Facebook—bought Slide. Slide had an incredible run at Google. Google announced it purchased the company on August 6, 2010, for $182 million, and then Google announced it was killing the company August 26, 2011. During those 387 days of operating under Google, Slide did the obvious thing and made a messaging app.

It was called „Disco.“

To start, it was only for iOS and only worked in the US. I feel like this app is mostly lost to time, due to only being alive for a year and mostly having a low profile during that time. The best report I can find is from Business Insider, which, in a wonderful time capsule, describes the app as „another one of those group texting apps everyone keeps talking about.“ Group messaging was apparently novel enough at the time for this kind of commentary. BI continued: „Disco is late to the game and already a bit behind in the features other group messaging apps have“ and compared it unfavorably to GroupMe, which launched a year earlier.

Group chat is not actually supported by SMS (that’s MMS, and it was not well supported at the time), but Disco did its best to turn single-target SMS into a group chat anyway. You could create a new group with the Disco app, which would generate a new phone number for the group. You and your group chat cohorts would all send their messages to this one Disco number, and Disco forward the messages to everyone else, prepended with their contact name. The Disco app didn’t actually do much. It was used for managing groups, and users could add a group number to your contacts. After that, all the actual texting happened in the iPhone SMS app. I’m going to guess this wasn’t an over-the-top messaging service for political reasons. Like we covered with Google Voice, AT&T and Apple would not have liked any service that „duplicated functionality.“ Disco still counted against your carrier’s SMS billing, though, so everyone was happy.

There wasn’t much more to Disco than this. That Business Insider report actually criticized Disco for a lack of features like „location sharing or group calling.“ Digging through the site’s Archive.org history reveals that eventually there was an Android app, and at one point you could even send messages to Disco from the web at disco.com.

Slide and Disco are both things you can add to Google+’s considerable body count. The initial blog post title, „Google and Slide: building a more social web,“ should tell you all you need to know about what happened to Slide at Google. Google+ was launching in about a year, and like all competing Google projects, Slide needed to be ground up and fed to the new social beast.

The Google+ Era (2011)—Google’s social panic

Looking back, it’s almost hard to recall the deranged fever dream that was the Google+ era. Social media was a serious fad in 2011, and after the failure of Orkut, Jaiku, and Google Buzz, Google didn’t have a social horse to bet on. Facebook had a stated goal of signing up every single human on the planet, and while it seems ridiculous today, Google saw Facebook as an existential threat. The thought was something along the lines of, „What if people ask their social graph instead of doing a Google search?“ as if asking a gaggle of people from high school was somehow equivalent to doing actual research. (Don’t do this. That’s how you get anti-vaxxers.)

Google went into a complete panic over its lack of social platform, and on June 28, 2011, Google+ was born. In addition to a regular Facebook-style social networking site, Google+ was a hyper-aggressive, all-consuming social backbone that would run through most major Google services. If users wouldn’t voluntarily use a Google social service, Google would make all of its services into a social service. The best quote showing how intense this was going to get came from Google executive Steve Grove, who dropped this doozy of a line: „Google+ is kind of like the next version of Google.“

The motivation for Google+ came directly from the top. Earlier in 2011, then-CEO Larry Page tied all employee bonuses to the success of Google+. Very little at Google is done via a top-down directive like this, making Google+ one of Google’s only products that seemed like a unified effort. Google’s typical lack of unity is why you see so many messaging apps. Android’s SMS app is handled by the Android team, and they don’t really need to talk to anyone else. Google Voice was an acquisition and created its own team. Wave was a new project started by the Google Maps founders. Google Buzz was from the Gmail team.

Some companies with strong leadership can move toward a singular goal as a big unit, but with Google, working together was such a foreign concept that management had to bribe every individual employee with this bonus plan. I maintain that this is the only time Google has done something together as a company. The rest of the time, it’s individual teams making autonomous decisions.

The core Google+ site was a pretty basic, Facebook-style social networking app, with posts, comments, and „+1″s instead of likes. The one big innovation was the concept of „Circles,“ Google+’s group-sharing mechanic. Instead of everyone being a „friend“ like on Facebook, Google+ had users build several social circle lists, so you could have lists like „Co-workers,“ „Close friends,“ and „Family“ and choose to share various things with each of them since each post had a checkbox sharing UI. This seems like a direct reaction to the outcry of Google Buzz, which shared everything with everybody. For Google+, Google said, „You want sharing options? Here are all the options you could want!“

Google learned very little from Google Buzz when it came to shoving social services inside established apps, though. Over the next few years, Google+ would be built into nearly every Google product. A top navigation banner across Google’s suite of services included your Google+ profile and a live notification count. Google Search results integrated Google+ content, mixing in private data with public search results and letting users „+1“ sites. For some period of time, you couldn’t make a new Gmail account without also making a Google+ profile. Gmail showed Google+ profiles associated with each email sender. The Google Play Store required a Google+ account to leave a review. YouTube required a Google+ account to leave a comment. Android used Google+ for photo backup and contact retrieval. Google Maps integrated reviews and photos from Google+ directly into business pages, and Google Latitude, Google Maps‘ location-sharing service, was killed in favor of Google+ location sharing.

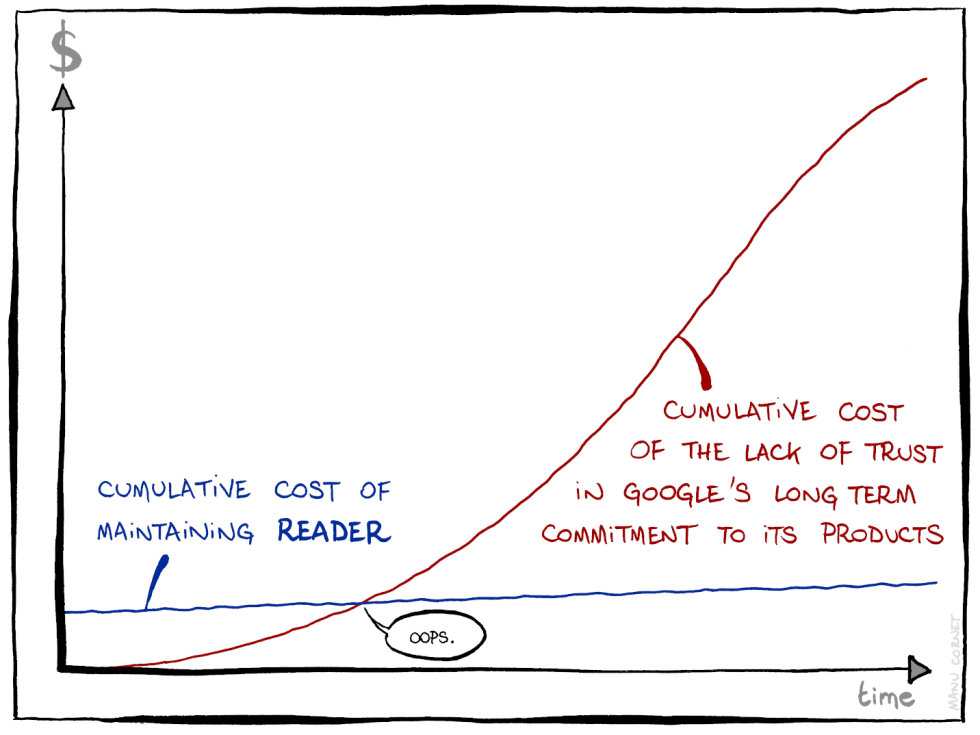

Google+’s greatest sin was the murder of Google Reader, a beloved RSS reader that some people still mourn to this day. Shortly after the service’s death in 2013, Reader’s ex-product manager revealed the team was borged into the Google+ collective sometime in 2010, which led to Reader’s death.

Google+ wasn’t all bad, though. It launched with „instant uploads“ for photos, leading to what would eventually become Google Photos, one of Google’s best new(ish) products.

Google+ Hangouts video chat—The first Hangouts

Besides the social network and borging everything into the Google+ collective, the service’s 2011 launch included a group video chat platform called „Google+ Hangouts.“ Note that this is completely unrelated to the „Google Hangouts“ chat service that would launch in 2013—it was just video chat.

Hangouts video chat had a novel interface that would show thumbnails of users at the bottom of the screen, and it automatically switched the main view to whoever was talking at the time. There was a text chat on the side and a few face-tracking special effects. You could even watch YouTube videos as a group.

While Google+ was not always looked on favorably, Google+ Hangouts was a big hit. Lifehacker called it, „The best free group video chat we’ve seen.“ In 2012, Google added a feature called „Hangouts on air,“ which would broadcast your group conversation on YouTube, basically making it the defacto standard for group conversation podcasts. Broadcasting a group video chat over YouTube was a great collaboration between Google services, so naturally, Google killed the feature in 2019 and never really launched a replacement.

Google+ Hangouts launched with 480p video only, and it needed a browser plugin to work—the same plugin used for Google Talk. In 2013, Hangouts video chat turned on HD 720p video chat when it switched from H.264 to Google’s open source video codec, VP8. In 2014, Google switched over to WebRTC, the „RealTime Communication“ standard for browsers, allowing Google Hangouts to do video chat without a plugin.

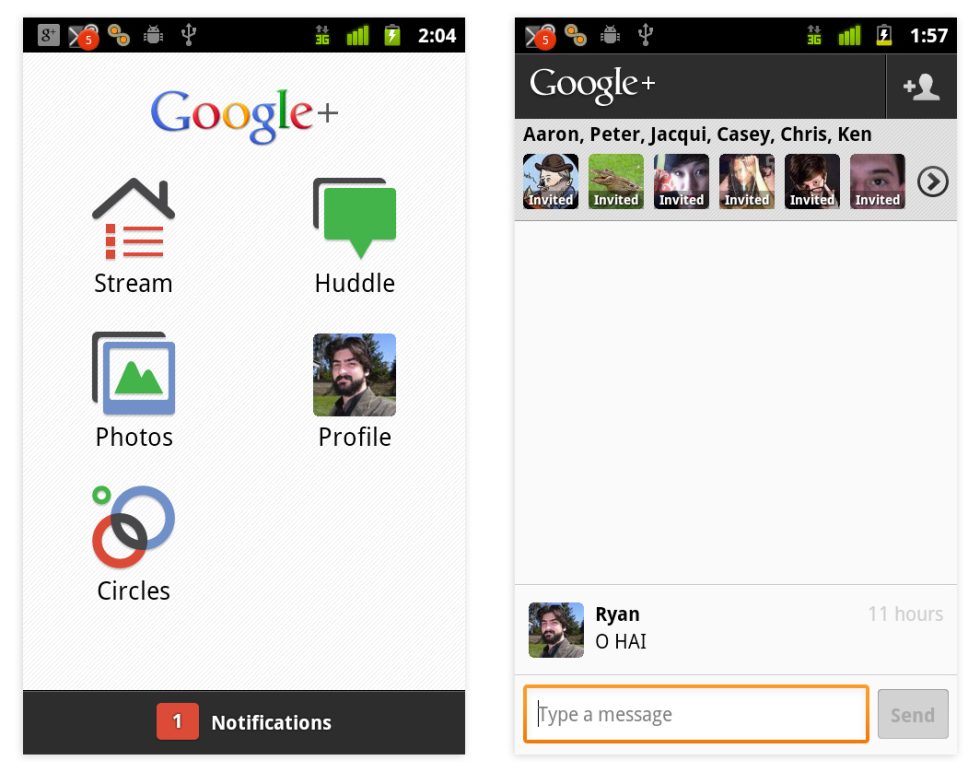

Google+ Huddle/Messenger—I guess we should have some kind of DM function

Lifetime: June 28, 2011—August 14, 2013 (2 years, 1 month)

Clients: Android and iOS

Google+’s very first messaging service was „Google Huddle,“ a name that almost no one remembers. That’s because Google Huddle launched with G+ in June 2011, but this service became „Google+ Messenger“ by September 2011. Apparently, there used to be a startup called Huddle that owned the global trademark, and Google quickly agreed to change the name. Whoops.

Google+ Huddle Messenger was an exclusively mobile group messaging service. Google+ always had a „mobile-first“ design, but for some reason, for Google+ Messenger, „mobile-first“ got turned into „mobile-only.“ This was a constant source of frustration for users. Messenger was just the world’s most basic group texting app, and you could invite anyone in your Google+ circles to join.

The service got a front-page promotion on the Google+ Android and iOS apps, but other than that, it never really went anywhere. You could send text—and only text—to a group… and that was it. It made sense to be able to DM people on Google+, but did it make sense for that app to be the totally siloed Google+ Messenger mobile app? Not really. Messenger always felt like an afterthought, and after two years of zero improvements, the feature was killed on August 14, 2013.

A competitor emerges—iMessage has entered the chat

Lifetime: October 12, 2011-Present

Clients: iOS, macOS, WatchOS

And now, a brief history of Apple Messaging services: iMessage. End of article.

Apple launched iMessage along with iOS 5 in October 2011 and brought iMessage to the Mac with the release of OS X 10.8 Mountain Lion the next year. Apple did not release a second, competing messaging app 18 months after the launch of iMessage. In fact, Apple has never launched a competing messaging app in the nine years this service has been around. The full power of the company is behind iMessage with no other distractions.

iMessage quickly became the template for what users wanted from a Google Messaging system. Apple’s service was the SMS client on iOS, but it also pushed people over to the enhanced iMessage service whenever possible. Therefore you could use iMessage to communicate with everyone, no matter what. As Apple was fond of saying at the time: it just worked. iMessage messages synced to your Mac, and eventually, SMS forwarding arrived in 2014, so I guess you can say that’s when the service fully powered-up.

We’ll later see Google acquiesce to the wishes of carriers and put SMS on a pedestal, but Apple was the polar opposite. Cupertino couldn’t care less about the feelings of AT&T et al. Carriers were apparently blindsided by the announcement of iMessage and Apple’s commandeering of SMS. I think it’s funny that this happened the same year AT&T’s iPhone exclusivity ended and Verizon finally got to launch an iPhone. I like to imagine Apple said something like, „Hey carriers, multiple partners means you are all now considerably less valuable to Apple! We’re going to kill SMS. If you don’t like it, there’s the door.“ The truth, though, is that Apple didn’t even feel the carriers were important enough to communicate with them.

We’re not covering the full history of iMessage, but naturally having the full weight of Apple behind the service makes it a very competitive messaging app. It has group chat, end-to-end encryption (for iMessage messages), voice messages, FaceTime video calls, and a million other features.

The big downside to iMessage is that it only works on Apple products, and there’s no website, which is pretty limiting compared to the usual „works with everything“ client smorgasbord from (good) Google products. Just like BBM, Apple views this as a type of lock-in, though. Apple is a hardware company, and you’re supposed to only buy Apple products. This also means Apple sees iMessage as a solvent business since more lock-in means more hardware sales.

The hardware lock-in limits the install base iMessage can have, though, since not everyone wants or can afford Apple hardware. The result is that while iMessage is great, you won’t see it on a „most popular messaging services“ list.

One more competitor—WhatsApp is now worth $22 billion

By 2012, WhatsApp had become one of the world’s most popular messaging apps and was announcing explosive metrics like 10x more messages per day than it had seen the year before. The app doesn’t have much of a presence in the US, but it is extremely popular in India, Europe, Africa, and Latin America. In late 2012, rumors started swirling that the then-independent company was taking acquisition bids. The first bit of smoke was from a TechCrunch report in December 2012, saying that Facebook was sniffing around. WhatsApp shot the rumor down publicly, calling it „not factually accurate.“ Next up was an April 2013 report from DigitalTrends saying Google was negotiating a WhatsApp buyout for $1 billion. WhatsApp shot down this report, too.

It’s hard to believe any of WhatsApp’s denials since just a year later, the company really did end up selling—to Facebook—for a deal that ended up being valued at $22 billion. There was apparently a bidding war going on, and, according to a report from Fortune, Google tapped out at $10 billion. Google’s $10 billion bid would have been the company’s second-largest acquisition ever, after Motorola. Instead, Facebook’s valuation of the messaging market was in a completely different league from Google’s, and it turned the deal into one of the biggest tech acquisitions ever.

WhatsApp was a company that was only five years old at the time and had only 50 employees, yet it ran rings around Google’s messaging efforts (which is a truly embarrassing situation). It’s the perfect example of how harmful Google’s lack of focus can be. From 2009 to 2014, WhatsApp built a messaging app worth $22 billion that boasted 450 million users. From 2009 to 2014, Google launched five different messaging apps.

Pre-Facebook acquisition, WhatsApp also answered the question of, „How do you make money with a messaging service?“ WhatsApp made money through the innovative scheme of charging money—it cost $1 to sign up and $1 a year going forward. WhatsApp originally did this to slow user growth to a manageable amount and cover the cost of sending initial SMS sign-up texts. The founders were apparently shocked to see that $1 didn’t hurt people’s appetite for the app, and it just remained a paid app.

If Google had spent the money to buy WhatsApp, today it would probably be a messaging powerhouse. Instead, the messaging rich got richer, and Facebook was able to control the WhatsApp user base along with its already popular Facebook Messenger service. I think most observers would say Facebook understands social networks and messaging more than Google could ever dream of, and it’s interesting that Facebook treats messaging as a pillar of the company. It’s something the company is willing to spend tens of billions of dollars on, while Google is content to let messaging languish as a series of unstable side projects.

We recently got an amazing bit of commentary on this series of events from Apple, which ended up having some of its internal communication aired out in public thanks to the Epic Games case against the company. When the first „Google’s buying WhatsApp!“ rumors started swirling, Apple’s SVP of Internet Software and Services, Eddy Cue, started pitching the idea of a response to what he saw as a formidable Google/WhatsApp combination. Cue asked the other Apple execs, „Do we want to lose one of the most important apps in a mobile environment to Google?“

Hearing a high-ranking Apple exec call messaging „one of the most important apps“ is, again, strikingly different compared to how Google normally runs messaging. At any point in the last 15 years, messaging has almost always been a complete afterthought in the company’s lineup. Cue wanted to respond to Google/WhatsApp by going really hard and bringing iMessage to Android instead of keeping it the Apple-ecosystem exclusive it is today. Other execs were skeptical of the move, and the plan never happened, but it shows again how Google buying WhatsApp could have been a major turning point for the industry.

Cue (and Facebook) were definitely right about the future of WhatsApp. WhatsApp had 450 million monthly active users at the time of the Facebook purchase, and today the app has grown to over 2 billion users. Google has released another five messaging apps in that amount of time and still doesn’t have a stable or successful messaging platform.

Google Docs Editor Chat (2013)—Just like Gmail chat, but not integrated with anything

Lifetime: June 6, 2006 (Sheets)/April 25, 2013 (Docs and Slides)-Present

Clients: Desktop web only

Let’s take a minor detour from the major messaging apps to talk about Google Docs. Google Docs/Sheets/Slides is a great online tool for collaborating on a document. And often when you’re collectively writing or editing something, you want to have a discussion about it. For that, the Google Docs Editors have a very handy integrated chat service.

Google Docs and Slides got a siloed chat feature in 2013, but if you want to get really technical, Sheets first had chat at launch, all the way back in June 2006, when it was „Google Spreadsheets Labs.“ The other Google office suite app would be more reliant on an in-line comment system for communication at first (does that count as a messaging service?), though, and it wouldn’t get a similar chat feature until seven years later.

This 2013 version of the Google Docs editor chat looked and worked just like Google Talk in Gmail. It actually was Google Talk under the hood, but somehow this wasn’t integrated with Google Talk. Google Docs throws everyone looking at a document into a single group chat, and combined with the fact that some documents could be public, maybe that didn’t jibe with Google Talk’s contact security model.

If Google could have made everything work, Gmail’s use of a real chat service still seems like a more convenient solution. While Google Talk works everywhere and will pop up on your phone, Google Docs Chat is awkwardly only available through the desktop web app, which means you’ll only get a message if you are sitting in front of a computer with that specific document open. I am always first invited to look at a Google Doc through a real messaging service, like Hangouts, and then at some point we have to awkwardly stop talking on Hangouts and start talking to Google Docs just to get the convenience of having everything in a single window. If I leave early and someone asks a late question, that question doesn’t arrive if it’s asked through Google Docs. The weird thing about Docs and Gmail is that the interfaces are nearly identical—pop-up chat boxes that you can type in—but Gmail’s is so much more reliable and convenient thanks to being plugged into a real chat service.

Like we discussed in the Google Talk section, thanks to sharing some back-end functionality with Google Talk, the 2017 shutdown of Google Talk disrupted Docs chat for a bit while it switched to Hangouts. What’s crazy about that timeline is that Google Docs and Slides implemented Chat in 2013, one month before Google Hangouts launched. This capped off months of rumors about Google’s new chat service, so surely the Google Docs team knew Talk was on the way out. Yet, it launched the feature based on Talk technology anyway. Skate to where the puck is going, people!

Google Hangouts (2013)—Google’s greatest messaging service

Lifetime: May 15, 2013 to Present

Platforms: Android, iOS, the web, web Gmail, Windows, Mac, Linux, Chrome OS, Android Wear, Google Glass

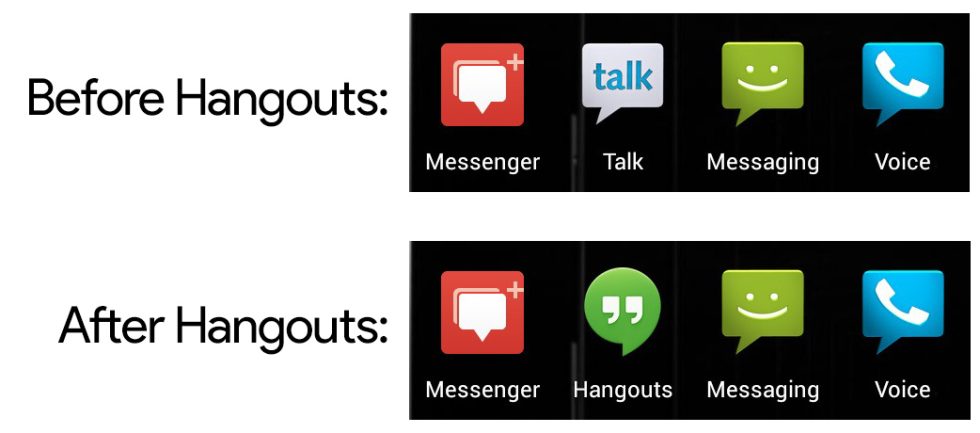

Circa 2013, Google was running into a problem—way too many messaging apps. If you were a Google user and wanted to message someone, you could IM them on Google Talk, send an SMS from Android’s texting app, send them an SMS through Google Voice, or fire up Google+ Messenger. Google’s plan to solve the problem of four messaging apps was… to develop a fifth messaging app.

This messaging app would eventually be a great unifier, though. Rumors of Google’s super messaging platform started as early as 2012, with one Google product manager admitting to the media Google was doing „an incredibly poor job“ meeting the needs of messaging users (you don’t say?). By 2013, rumors of an IM project codenamed „Babel“ were regularly popping up, promising a unified Google messaging solution.

At Google I/O 2013, Google announced that Hangouts would turn from a video app into a full-blown messaging service. During the presentation, Google pitched an idea that some messaging services still can’t offer: a client that can do text, photos, and video chat, across all devices, on any OS. On day one, Hangouts was everywhere. There were clients on Android, iOS, and on any desktop via the Gmail website or a standalone Chrome extension (which was indistinguishable from a native app). That last bit worked on Windows, Mac, Linux, and Chrome OS.

Hangouts‘ default list view showed conversations instead of people, mixing in one-to-one chats with group chats. Any photos shared to a room would be saved in a Google+ Photos album, and text history is saved forever (if you want) in Gmail and synced across devices. Hangouts‘ G+ integration meant you could add entire circles to your group chats or add people through a simple checkbox UI. Google Talk pre-dated the invention of Unicode-standard emojis, so Hangouts was Google’s first messaging service to ship with a comprehensive set of the little glyphs. There were read receipts and animated typing indicators, and since this was based on Google Hangouts the video chat app, a single button push could drop everyone into a group video call.

Google Hangouts replaced Google Talk, and the existing user base got an in-place upgrade, a move that should be a benchmark for how serious Google is about any given messaging app. In the future, a thousand Google Messaging apps will rise and fall after the launch of Hangouts, but only one, Google Chat, will be deemed worthy enough to inherit this user base. The desktop version of Gmail swapped out the Google Talk sidebar for a Hangouts sidebar, which was functionally very similar. On Android, Hangouts shipped as an upgrade to Google Talk, and to this day it has the same package name as Google Talk: com.google.android.talk.

The in-place upgrade strategy led to a huge overnight explosion of Google Hangouts users. Android would pass 1 billion activations in a few months, and Google Talk was a preinstalled app since the beginning. All of those still-active Android users would become Google Hangouts users once they checked for app updates. A year earlier, Google announced Gmail was the world’s biggest email service, with 425 million active users. Now all of these people were on Hangouts.

Hangouts also started the death of XMPP messaging for Google’s biggest messaging service. All the federation work that Google started with Google Talk wasn’t making the jump to Hangouts. XMPP clients like Adium and Pidgin could still connect to Hangouts, but they would have to do it with Google credentials. Non-Google users wouldn’t be able to connect to the Hangouts service through a federated server the way they could with Google Talk. Even with Google credentials, XMPP clients on Hangouts were second-class citizens and didn’t get access to many features.

On day one, Hangouts was a bit of a disappointment. Those hoping for a unifying Google messaging service, like the rumors promised, didn’t get one. We started with four services—Google Talk, Android SMS, Google+ Messenger, and Google Voice. And in the immediate aftermath of the Hangouts launch, there were still four services—Hangouts, Android SMS, Google+ Messenger, and Google Voice. Nothing was actually unified. There were also a few missing features compared to Google Talk, like the lack of audio calls and presence indicators. This is the minimum viable product launch strategy in action, and the disappointment is standard. A lot of Google services never recover from the initial negative reaction, but Hangouts did.

The key to overcoming MVP disappointment is to rapidly ship updates, and Hangouts did that. Three months after launch, in August 2013, Google+ Messenger was killed, and the company was down to three messaging apps. October 2013 brought the long-anticipated Hangouts SMS integration on Android. Users could register Hangouts as the default SMS app, finally giving Android users an equivalent to Apple’s iMessage on iOS. That month also brought the release of Android 4.4 KitKat, where there was no default „SMS“ app for Android anymore, there was only Hangouts (so if counting, we’re down to two apps). Google finally delivered on the full promise of Hangouts when, by late 2014 around a year and a half after launch, Hangouts finally added Google Voice support. These features all arrived slower than any Hangouts user would like, but finally, there was one Google messaging app to rule them all.

At this point in 2015, Google Hangouts was at the height of its powers. To date, it’s still the greatest messaging service Google has ever produced. It worked on every platform. It pulled in SMS, Google Voice, and regular Hangouts messages. They were all stored in a seamless, merged history of messages from each contact, and you could switch message delivery systems via an easy drop-down menu. It had most of the features you could want, like video calls and location sharing. And accordingly, by June 2015, the app hit a billion downloads, just on Android. A dedicated Hangouts website, hangouts.google.com, would launch in August.

The death of Hangouts, unified Google messaging, and hope

Hangouts‘ reign as Google’s unified messaging service held together for about one year, basically the entirety of 2015. By the end of December, Google couldn’t help itself and there was already talk of a new Google messaging service that was gearing up to launch, but this time with chatbots (this would eventually be Google Allo). Also in 2015, Hangouts development was already going slower than people would like, and the neglect was starting to be visible.

Google actually caved on an iMessage-style SMS takeover a year earlier, in 2014. The company pushed forward the bold direction of running all SMS messages through Hangouts in the 2013 release of Android 4.4 KitKat, which didn’t include any other SMS app. Carriers complained soon after, and Google immediately sided with carriers over users, shipping what the company described as a „carrier-centric“ SMS app, Google Messenger, in Android 5.0 Lollipop. Around 2014, the iOS/Android duopoly was not set in stone yet, and with Google still fighting Windows Phone 8, it didn’t want to upset carriers and give Microsoft an opening for success. Hangouts‘ SMS support would still hang out for a few more years, but Google proved it didn’t have the stomach to do anything the carriers didn’t enthusiastically approve of.

Hangouts collapsed about as quickly as it was built. Despite the superior functionality on Hangouts, Google started pushing users to switch SMS usage from Hangouts to the „carrier-centric“ Google Messenger SMS app in early 2016. At Google I/O 2016 in May, Google Allo was announced, a new messaging service that would ship with lots of bells and whistles that could have been helpful to Hangouts. By October 2016, Hangouts was no longer a default Android app, having lost its spot to Allo.

Hangouts started being stripped of features, but it was never enough to kill the app. In May 2017, Hangouts was stripped of its SMS functionality. In December 2018, Google announced a formal plan to kill Hangouts and transition users (many of whom have been around since Gtalk) over to yet another Google Messaging app, Google Chat, which was first built as a competition to Slack for G Suite. The Wear OS Hangouts app died in 2019, and location sharing and audio calls were ripped out of Hangouts in 2020.

Yet actually killing Hangouts has proven incredibly difficult for Google—mostly due to how many clients there are and how widespread it is. Despite the late 2018 shutdown announcement, Google hasn’t made a ton of progress in 2019 and 2020 toward replacing Hangouts. The latest timeline said that optional upgrades for consumers to Google Chat will start in 2021, and Google Voice support will die in 2022. There’s still no actual shutdown date.

Google Hangouts was the gold standard of Google Messaging apps, and the app has cast a long, dark shadow over all of Google’s up-and-coming messaging services. From here on out, any complaints about newer Google Messaging services almost always revolved around the quote, „Hangouts did this better.“ If Google could have just taken care of Hangouts over the years and thrown the full weight of the company behind this single messaging service, today it might have an iMessage-fighting, WhatsApp-rivaling message app, and I probably wouldn’t be writing this article. Google just could never throw the full weight of the company behind a single messaging app, and soon Google would move on to a new shiny bauble, leaving Hangouts to rot.

Google Spaces (2016)—A messaging app for Google I/O 2016 attendees

Lifetime: May 16, 2016—March 3, 2017 (8 months)

Platforms: Android, iOS, the Web

Google was really in the messaging mood at Google I/O 2016, where the company launched not one, but two messaging apps. The first was a completely baffling app called „Google Spaces,“ a group messaging service for „small group sharing.“

Spaces were basically chatrooms that you could share stuff to. You could create a room around a certain topic, invite people to it via a URL, and then people could post messages, photos, and links into the room. That was pretty much it. There were apps for the web, Android, and iOS, and the mobile apps would ship you notifications whenever someone posted a new message. Each space room looked identical to a messaging app, while an „activity stream“ would show all the new stuff from all your spaces (that looked like a social network stream).

Spaces‘ only unique feature was the odd choice to have Google Search „built-in.“ Instead of just copying and pasting a link to something from an outside app, Spaces would let you fire up a built-in web browser and navigate around the web. The Spaces web view would pin an easy „share to space“ button at the bottom of the screen, but was copying and pasting a link really that difficult?